Kraftvolle Ladungssicherung

Stausäcke zur Ladungssicherung (Staupolster) aus PP-Gewebe oder Kraftpapier werden in Ladelücken platziert. Durch die Befüllung des Stausacks mit Luft wird verhindert, dass Ladegüter in Bewegung geraten können. So leistet der Stausack einen wichtigen Beitrag zum Schutz Ihrer Fracht. Diese Polster werden vorwiegend im Container, zunehmend aber auch auf LKW eingesetzt.

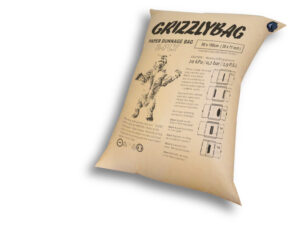

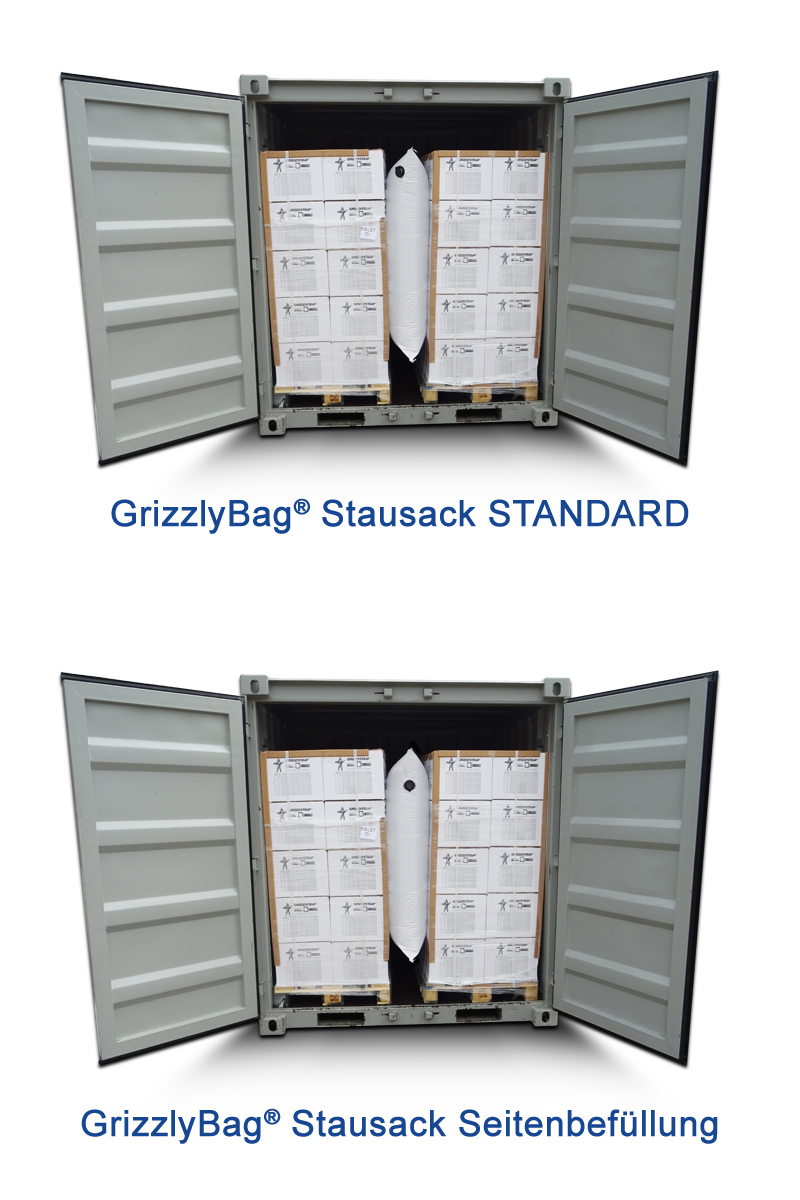

Wir bieten Ihnen unterschiedliche Stausacktypen in unterschiedlichsten Abmessungen an. Ob nun der GrizzlyBag® Stausack mit innovativer Schnellbefüllung oder der klassische Stausack mit Silikonventil – Sie entscheiden, welches Ihr Staupolster sein soll.

| Schnell. Schneller. GrizzlyBag®Neu entwickelte Füllgeräte leiten den Luftstrom in einen speziellen Venturi-Adapter. Der dort entstehende Unterdruck saugt über Öffnungen Umgebungsluft an und bläst diese beim Befüllen des Stausacks zusätzlich in den GrizzlyBag®. Mit dieser Innovation sparen Sie 50% Zeit beim Befüllvorgang. |

Nehmen Sie Kontakt zu uns auf! Unsere kompetenten Vertriebsmitarbeiter analysieren gerne gemeinsam mit Ihnen die Beschaffenheit Ihrer Ladung und finden so den optimal geeigneten Stausack für Ihre spezielle Anwendung.

FAQ – Stausäcke

Stausäcke, auch bekannt als Staupolster oder Dunnage Bags, sind luftgefüllte Polster, die zur Ladungssicherung im Transportwesen verwendet werden. Sie werden in Hohlräumen zwischen der Ladung und den Wänden des Transportmittels platziert, um ein Verrutschen, Kippen oder Umfallen der Ladung während des Transports zu verhindern.

Funktionsweise:

- Platzierung: Die Stausäcke werden in den Ladelücken platziert, um die Lücken zwischen der Ladung und den Wänden des Transportmittels zu füllen.

- Befüllen: Die Stausäcke werden mit Luft befüllt, bis sie fest gegen die Ladung und die Wände des Transportmittels gedrückt werden.

- Sicherung: Die Luft im Stausack erzeugt eine formschlüssige Verbindung zwischen der Ladung und den Wänden des Transportmittels, wodurch die Ladung an Ort und Stelle gehalten wird.

Vorteile:

- Effektiv: Stausäcke können verhindern, dass Ladung während des Transports beschädigt wird.

- Einfach: Stausäcke sind leicht zu platzieren und zu befüllen.

- Kostengünstig: Stausäcke sind eine preiswerte Möglichkeit, Ladung effektiv zu sichern.

Einsatzbereiche:

Stausäcke werden in verschiedenen Bereichen eingesetzt:

- Containertransport / Seefracht: Stausäcke werden vorrangig im Containertransport eingesetzt, um die Ladung im Seecontainer zu sichern.

- Eisenbahnverkehr: Stausäcke werden auch im Eisenbahnverkehr eingesetzt, um die Ladung in Güterwagen zu sichern.

- Lkw-Transport: Stausäcke werden zunehmend auch im Lkw-Transport verwendet, um Paletten und andere Güter zu sichern.

Materialien:

Stausäcke werden aus unterschiedlichen Materialien hergestellt:

- Polypropylen (PP): Ein starkes und reißfestes Material, das für die Außenhülle verwendet wird.

- Polyethylen (PE): Ein leichtes und flexibles Material, das für den Innensack (Inliner) verwendet wird.

Fazit:

Stausäcke sind ein effektives und kostengünstiges Hilfsmittel zur Ladungssicherung. Sie sind einfach zu verwenden und können in verschiedenen Bereichen eingesetzt werden.

| Der Stausack wird in der Ladelücke platziert. |  |

| Der Stausack wird optimal positioniert. |  |

| Der Sack wird dann über ein Füllgerät mit Luft befüllt. |  |

| Das Staupolster dehnt sich in der Lücke aus. |  |

| Die Füllgerät wird vom Ventil entfernt. |  |

| Der Ventildeckel wird verschlossen. |  |

| Der Druck in dem Staupolstersack stabilisiert die Fracht. |  |

Die Fracht kann nun nicht mehr umkippen oder verrutschen!

Der nachfolgenden Tabelle können Sie die maximalen Freiräume (Ladelücken) entnehmen, welche unsere Stausäcke ausfüllen können:

| Breite des Stausacks | Freiraum (Ladelücke) |

| 60 cm | bis 20 cm |

| 90 cm | bis 35 cm |

| 120 cm | bis 45 cm |

| 150 cm | bis 55 cm |

Das ist abhängig vom ausgewählten Stausack. Klicken Sie einfach auf den jeweiligen Link zum Shop. Dort finden Sie die derzeit verfügbaren Abmessungen und Preise.

Bei Venturi-Füllgeräten entsteht durch ihre spezielle Bauform ein Unterdruck. Dieser Unterdruck saugt über Öffnungen Umgebungsluft an und bläst diese beim Befüllen des Stausacks zusätzlich in den GrizzlyBag®. So kann ein Stausack mit entsprechendem Ventil etwa doppelt so schnell wie mit einem herkömmlichen Adapter befüllt werden.

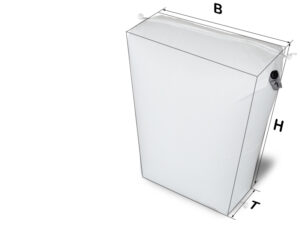

Die genaue Position der Ventile entnehmen Sie bitte der nachfolgenden Abbildung.

Nein, da durch die Wölbung der Stausäcke ein sicherer Halt nicht gewährleistet werden kann. Hier sollten Sie möglichst durch eine Änderung der Beladung die Lücke verkleinern.

Ist dies nicht möglich, können Sie solche Lücken mit unseren speziellen GrizzlyBag® 3D-Stausäcken oder alternativ mit dem neuen Stausack GrizzlyBag® TWIN füllen.

Der neue GrizzlyBag® TWIN (auf Anfrage)

Nein, da unbekannt ist, welchen Belastungen ein Stausack während des Transportes ausgesetzt war. Weder die Unversehrtheit der Außenhülle, noch die Dichtigkeit der Innenhülle können so sichergestellt werden. Wir raten daher dringend davon ab!

Unsere Stausäcke bestehen zu 100% aus recycelbaren Materialien. Die Stausäcke lassen sich daher einfach und sicher durch Recycling stofflich verwerten. Dabei werden die Ausgangsmaterialien so aufbereitet, dass daraus wieder vermarktungsfähige Sekundärrohstoffe werden.

| Allgemeines Recycling-Symbol |

| Polyethylen Low-Density |

| Polypropylen |

| Papier |